Sorting through the various types of plastics can be daunting, whether you’re deciding on the right material for a project or trying to recycle properly. Consider this: an estimated 300 million tons of plastic are produced globally each year.

This blog post will guide you through seven distinct types of plastic, helping to clear up confusion and make informed decisions about their use and disposal. Get ready; we’re diving into the world of polymers with insights that might just transform your view on everyday items!

Understanding the Different Types of Plastics

Plastics come in a vast array of types, each with its own unique properties and applications. Think of plastics as a family tree with different branches for categories like thermoplastics and thermosetting polymers.

Thermoplastics soften when heated and can be molded into new shapes that they maintain upon cooling. Examples include polyethylene terephthalate (PET), often used for water bottles, or high-density polyethylene (HDPE), which you’ll find in sturdier containers like milk jugs.

Different plastic types also vary widely in their resistance to heat, chemicals, and impact. Polyvinyl chloride (PVC) is known for its durability and is commonly used for pipes in plumbing because it doesn’t corrode easily.

Meanwhile, low-density polyethylene (LDPE) lends itself to flexibility; it’s what makes grocery bags easy to carry yet strong enough not to tear under weight. Each type plays a specific role based on its molecular structure – like how long polymer chains give strength or how additives can create variations, such as more rigid or clear materials – making them indispensable in industries ranging from food packaging to construction.

Polyethylene Terephthalate (PET)

Polyethylene Terephthalate, commonly known as PET or PETE, is a type of plastic renowned for its versatility and recyclability. It’s perhaps most recognized as the material used to make beverage bottles and food containers.

PET’s popularity stems from its ability to keep out oxygen, which helps preserve the freshness of the products it holds. Manufacturers favor this plastic because it offers excellent clarity and strength while being lightweight.

These qualities ensure that items such as bottled water are safe for consumption over an extended period.

Molded into various forms through processes like injection molding and extrusion, PET finds use in numerous everyday items beyond bottles – including packaging films, synthetic fibers for clothing, and thermoforming applications like egg cartons.

Its clear appearance resembles glass but without the added weight or fragility. With high demand across industries ranging from food packaging to fashion textiles, recycling programs specifically target this plastic to reduce environmental impact.

As part of a commitment to sustainability, recycled PET (rPET) can be transformed back into many of these same products multiple times over its life cycle without significant loss in quality.

High-Density Polyethylene (HDPE)

High-Density Polyethylene, or HDPE, is a strong plastic known for its high strength-to-density ratio. It’s used to make many products like milk jugs, detergent bottles, and toys because it resists moisture, which prevents the growth of bacteria.

This feature makes it an excellent choice for containers that store food items or cleaning supplies. HDPE also withstands harsh chemicals and does not leach harmful substances into the contents it holds, ensuring safety for users.

Manufacturers favor HDPE for heavy-duty applications such as industrial piping systems, outdoor furniture, and plastic lumber due to its durability against weathering and ability to hold up under higher temperatures.

Its toughness allows it to handle being dropped or roughly handled without cracking easily. Furthermore, this versatile material can be recycled efficiently – identified by recycle code 2 – making it a preferred option in efforts toward sustainability and reducing pollution from single-use plastics.

Polyvinyl Chloride (PVC)

Polyvinyl chloride (PVC) is utilized in a wide range of products, including pipes, windows, and medical equipment. It is known for its durability and resistance to chemicals and weathering.

The production process involves combining vinyl chloride monomers through polymerization. PVC’s versatility makes it suitable for various applications due to its ability to be rigid or flexible based on the addition of plasticizers during processing.

PVC has drawn attention due to concerns about potential health and environmental impacts stemming from additives like phthalates and lead stabilizers used in some formulations. However, advancements in technology have led to the development of alternative formulations that are free from harmful compounds, such as bio-based plasticizers.

Moreover, PVC possesses excellent electrical insulation properties that make it ideal for use in cables and wiring applications without compromising safety standards.

Low-Density Polyethylene (LDPE)

Low-density polyethylene (LDPE) is a type of plastic known for its flexibility and toughness, making it suitable for various applications. It is commonly used in packaging materials such as plastic bags, shrink wraps, and container lids due to its ability to stretch without tearing.

LDPE also finds use in agricultural films, coatings for paper cartons, and flexible tubing due to its resistance to moisture. The versatile nature of LDPE makes it an ideal choice for products like squeezable bottles, soft toys, and wire insulation.

Its durability and transparency make LDPE a popular option in creating transparent bottles or containers.

Manufacturers favor LDPE not only for its physical properties but also because it can be easily processed using methods like injection molding and blow molding. This versatility has made LDPE a valuable material in the production of items such as household goods, disposable gloves, and even playground structures.

Overall, the unique characteristics of low-density polyethylene make it an essential component in many everyday products that people rely on.

Polypropylene (PP)

Polypropylene, or PP, is a type of plastic known for its versatility and durability. It is commonly used in packaging, textiles, and automotive components due to its resistance to moisture and chemicals.

PP is also widely used in food containers, dishwasher-safe food storage containers, reusable microwaveable plastic containers – thanks to its heat-resistant properties. This makes it a go-to choice for many consumer products.

Additionally, it’s also environmentally friendly as it can be repurposed through recycling.

PP boasts high melting points and resistance to fatigue, making it ideal for applications like living hinges (like those on flip-top bottles) that are subject to repeated stress. Its low specific gravity ensures lightweight parts with stability – the perfect combination for cost-effective solutions across various industries from automobiles to medical devices.

Polystyrene (PS)

Polystyrene, also known as PS, is a widely used plastic with a broad range of applications. It is often encountered in our daily lives as it’s utilized to make disposable cups, packaging materials, and even foam insulation.

The versatility and lightweight nature of polystyrene make it popular for various purposes. Its ability to be molded into different shapes while retaining its strength and durability makes it valuable in the production of consumer goods and building materials.

Polystyrene can be found in two forms: solid (used in items like CD cases) or foam (commonly known as Styrofoam). However, despite its widespread usage due to its low cost and versatility, there are concerns about the impact on human health and the environment associated with polystyrene.

These factors have led to ongoing efforts to find more sustainable alternatives that address these concerns without compromising functionality.

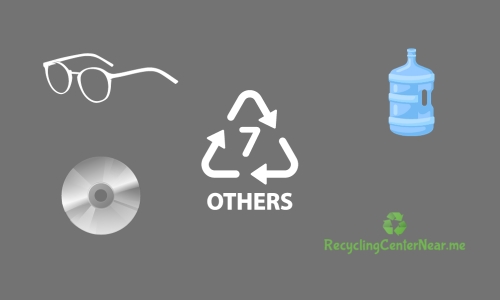

Other Common Types of Plastics

Polycarbonate, often identified by the recycling symbol “PC,” is a sturdy and transparent plastic commonly used in consumer products like DVDs, sunglasses, and even work surfaces. This type of plastic is valued for its heat resistance and durability, making it a popular choice for items that require strength and transparency.

Another common type of plastic is Acrylonitrile Butadiene Styrene (ABS), which boasts excellent impact resistance. It is favored in various industries due to its ability to withstand physical stress without breaking easily.

Polyester resins are another significant category of plastics distinguished by their molecular composition. These resins are utilized extensively in the production of items such as bottles, containers, and clothing due to their exceptional strength and versatility.

In addition to these plastics, there are also thermoset plastics widely employed for electrical applications owing to their remarkable insulation properties. Elastomers, including rubber-like materials such as silicone or polyurethane rubbers, play a crucial role in various fields due to their flexibility and elastic nature.

Recycling and Disposal of Plastics

Plastic recycling is essential to reduce waste and preserve resources. Here’s a comprehensive guide on how to manage different types of plastic materials:

- Polyethylene Terephthalate (PET): Recyclable and often used in containers for soda, water, and other beverages. It can be recycled into new bottles or polyester fiber.

- High-Density Polyethylene (HDPE): Commonly recycled into new bottles, plastic lumber, and floor tiles. Widely accepted in curbside recycling programs.

- Polyvinyl Chloride (PVC): Not widely recycled due to the release of toxic chemicals during production and disposal. Proper disposal is crucial to prevent environmental harm.

- Low-Density Polyethylene (LDPE): Often used in plastic bags and wraps. Some grocery stores accept LDPE film for recycling.

- Polypropylene (PP): Used in yogurt containers, caps, and straws, it is often recycled with many facilities accepting it.

- Polystyrene (PS): Not commonly recycled due to low market demand and its lightweight nature, which makes it difficult to separate from other materials.

- Other Common Types of Plastics: Including nylon, acrylics, polycarbonate, and thermosets have varying degrees of recyclability; they should be disposed of according to local guidelines.

- Biodegradable Plastics: These plastics break down more easily but may not always be suitable for traditional recycling streams; composting might be an option in some cases.

- Sorting Plastics: Different types of plastics can’t be mixed together for recycling; they need to go through sorting processes at facilities or individuals should follow guidelines before disposal.

- Educating Consumers: Important in ensuring proper disposal methods are followed; public awareness campaigns can highlight the importance of segregating plastic waste based on types before recycling or proper disposal.

FAQs

1. What are the 7 types of plastic?

The seven types of plastic include PET, HDPE, PVC, LDPE, PP, PS, and Other which include various bioplastics and grades used in industry for products like bottles, flooring, and bearings.

2. How can I identify different plastics?

You can identify different plastics by looking for the recycling number on the bottom – it’s a code from 1 to 7 within three chasing arrows that tells you what type it is.

3. Why do plastics have different grades?

Plastics have different grades because each one has unique molecules and properties that make them suitable for specific uses like keeping food fresh or making toys safe.

4. How does heating affect plastic materials?

When you heat plastic materials they change; some might melt easily while others withstand high temperatures – this matters a lot when choosing the right type for things like cookware or electrical insulation.

5. Are all plastics bad for health due to BPA (Bisphenol A)?

Not all plastics contain BPA – this chemical is often found in polycarbonate plastics marked with recycle code number 7 but there are many BPA-free options available across all types of plastic goods.

6. Can we consider bioplastics as an eco-friendly option compared to other traditional plastics?

Yes! Bioplastics are made from natural raw materials such as cellulose and they break down easier than traditional petroleum-based plastics which can decrease harmful effects on our environment.